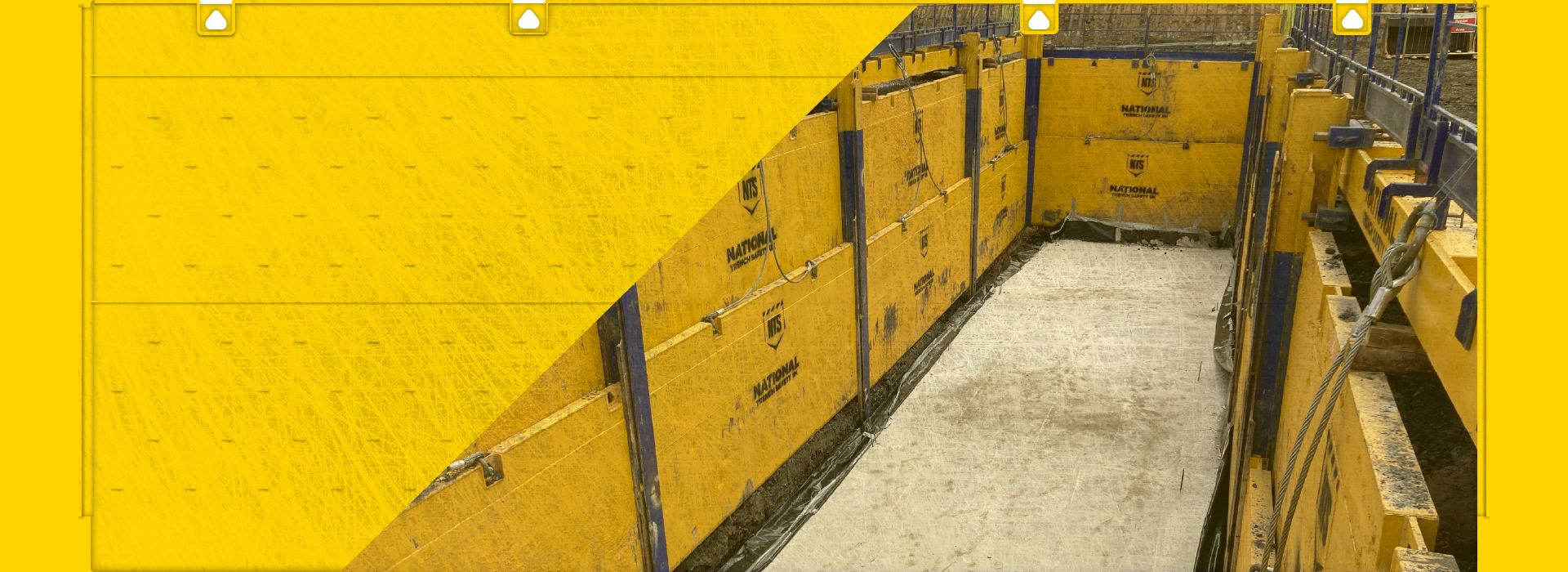

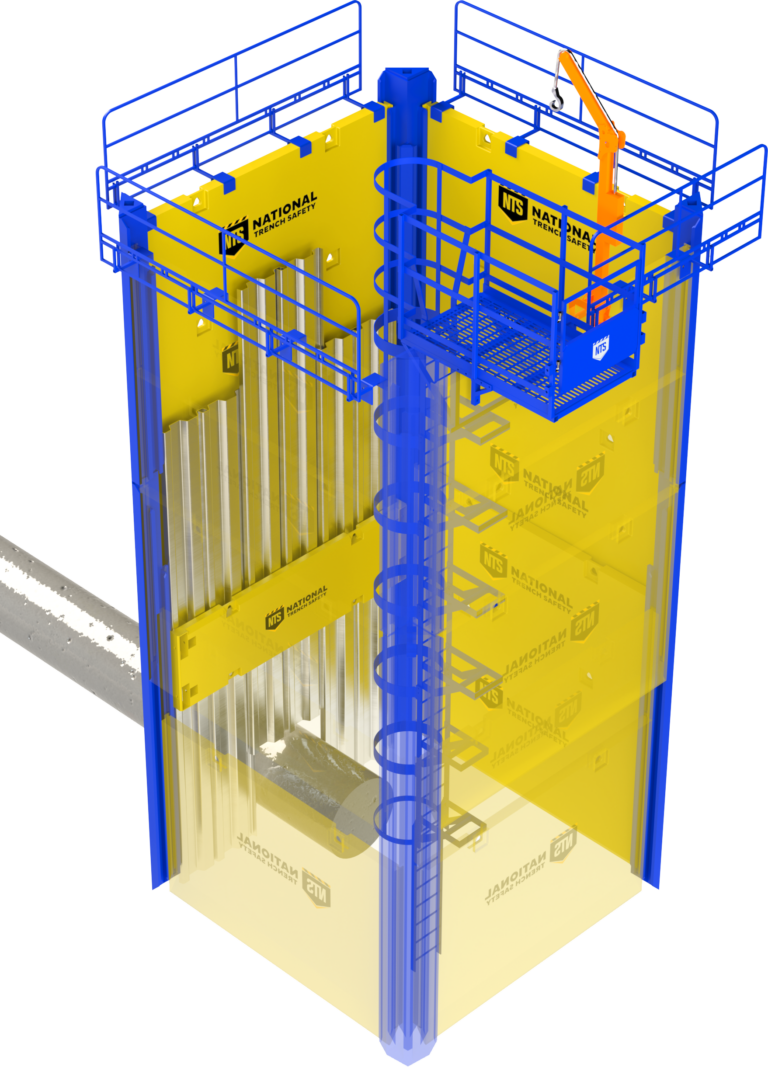

A MODULAR COMPONENT SYSTEM THAT IS USED IN PLACE OF DRIVEN TIGHT SHEETING.

A MODULAR COMPONENT SYSTEM THAT IS USED IN PLACE OF DRIVEN TIGHT SHEETING.

THE SLIDE RAIL SYSTEM, BY DESIGN, IS A MODULAR COMPONENT SYSTEM THAT IS USED IN PLACE OF DRIVEN TIGHT SHEETING OR BUILD-IN-PLACE SHORING SYSTEMS.